Steam engine plans offer detailed blueprints for building functional models or full-size engines. These designs provide step-by-step guidance, covering materials, tools, and assembly. Ideal for hobbyists and engineers, they ensure accuracy and functionality, catering to both historical and modern applications.

- PDF files and technical drawings are widely available.

- Plans range from simple model steam engines to complex industrial designs.

- They include specifications for key components like boilers and cylinders.

- Resources are accessible for both beginners and experienced builders.

Types of Steam Engines

Steam engines vary in design, catering to different purposes. Model steam engines are compact and ideal for hobbyists, while full-size engines are used in industrial applications. Both types require detailed blueprints for accurate construction.

- Model steam engines are popular for their simplicity and educational value.

- Full-size steam engines are powerful and often used in historical or specialized machinery.

- Plans include designs for vertical, horizontal, and oscillating engines.

Model Steam Engines

Model steam engines are popular among hobbyists and enthusiasts, offering a scaled-down version of full-size steam engines. These models are often used for educational purposes, teaching the fundamentals of steam power and mechanical engineering. They are typically smaller, more affordable, and easier to assemble, making them accessible to a wide range of builders.

Plans for model steam engines are widely available in PDF and blueprint formats, providing detailed instructions for construction. These designs often include specifications for materials, tools, and assembly steps, ensuring that even novice builders can create a functional engine. Many models are designed to replicate historical engines, preserving the heritage of steam power while allowing modern enthusiasts to experiment with the technology.

Some model steam engines are designed for specific applications, such as powering small machinery or boats. Others are purely decorative, emphasizing intricate details and craftsmanship. Regardless of their purpose, model steam engines remain a fascinating way to explore the principles of thermodynamics and mechanical engineering in a hands-on manner.

- Popular for hobbyists and educational use.

- Available in various designs, including vertical and horizontal layouts.

- Plans often include safety guidelines and maintenance tips.

Full-Size Steam Engines

Full-size steam engines are complex machines that have played a pivotal role in industrial history. These engines are designed for heavy-duty applications, such as powering locomotives, ships, and stationary machinery. Unlike model steam engines, full-size versions require significant resources, expertise, and space to construct and operate. Blueprints for full-size steam engines are highly detailed, ensuring precision in every component, from the boiler to the pistons.

Historically, steam engines were the backbone of the Industrial Revolution, revolutionizing transportation and manufacturing. Modern blueprints often draw inspiration from classic designs, such as the Improved Compound Robey Undertype Engine, while incorporating advancements in materials and efficiency. Constructing a full-size steam engine involves meticulous planning, specialized tools, and adherence to safety standards. These engines are not only functional but also serve as a testament to engineering ingenuity.

- Designed for large-scale industrial and transportation use.

- Require advanced technical knowledge and resources.

- Blueprints often blend historical designs with modern innovations.

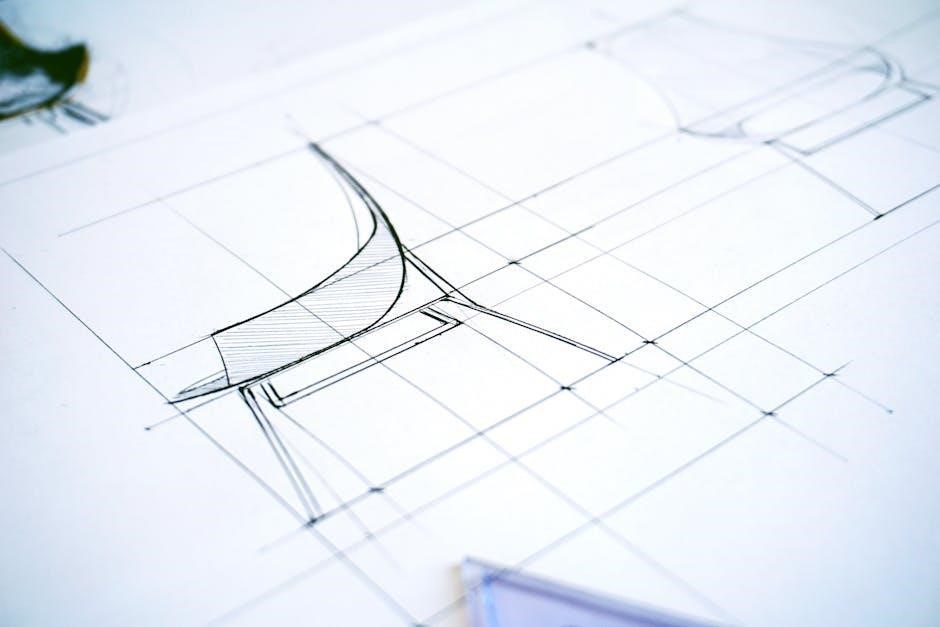

Design and Blueprints

Steam engine blueprints provide detailed technical drawings for constructing functional engines. These plans specify materials, dimensions, and assembly steps, ensuring accuracy and functionality. They often include diagrams for boilers, cylinders, and pistons, catering to both model and full-size engines.

- Detailed technical drawings for precise construction.

- Specify materials, dimensions, and assembly steps.

- Cover both model and full-size engine designs.

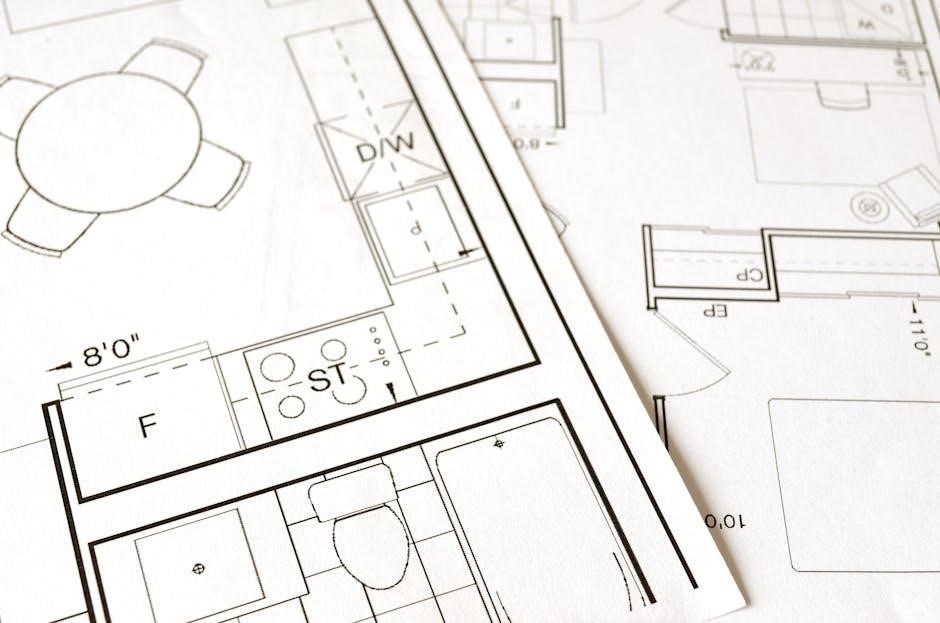

Key Components of Steam Engine Blueprints

Steam engine blueprints outline essential components, ensuring precise construction. The boiler generates steam, while the cylinder and piston convert thermal energy into motion. Valves regulate steam flow, and the crankshaft transforms reciprocating motion into rotation. These elements are meticulously detailed in PDF plans, providing clear instructions and measurements for accurate assembly.

- Boiler: Core component producing steam.

- Cylinder and Piston: Convert steam energy into mechanical motion.

- Valves: Control steam flow for efficient operation.

- Crankshaft: Transforms motion for rotational output.

Such blueprints are crucial for both model and full-scale engines, offering detailed specifications and assembly guidance.

Materials and Tools

Building a steam engine requires specific materials and tools to ensure durability and functionality. High-quality metals like steel, copper, and brass are commonly used for components such as boilers, cylinders, and piping due to their heat resistance and strength. Additionally, precision tools like lathes, milling machines, and drill presses are essential for machining parts to exact specifications. Welding equipment is also necessary for assembling and sealing critical joints, particularly in the boiler. Many PDF plans include detailed lists of materials and tools, guiding builders through the preparation process. Proper selection and preparation of these elements are crucial for a successful and safe steam engine build.

- Metals: Steel, copper, and brass for key components.

- Machining Tools: Lathes, milling machines, and drill presses.

- Welding Equipment: For secure and leak-proof joints.

- Fasteners: Bolts, nuts, and studs for assembly.

Having the right materials and tools ensures precision and safety in constructing a steam engine.

Assembly Steps

Assembly involves carefully following blueprint instructions to construct the steam engine. Start with the boiler, then move to cylinders, pistons, and valves. Ensure precise alignment and tightening of all components. Use specialized tools for fitting and welding critical parts.

- Boiler Installation: Core of the engine, requiring careful sealing.

- Cylinder-Piston Assembly: Ensures proper steam flow and compression.

- Valve Setup: Regulates steam intake and exhaust.

Follow detailed plans for a functional and safe engine build.

Workshop Preparation

Before starting your steam engine project, proper workshop preparation is essential. Ensure your workspace is clean, well-lit, and equipped with necessary tools and materials. A sturdy workbench and storage for parts are crucial.

- Tools Needed: Include lathes, drill presses, wrenches, and precision measuring instruments.

- Materials: Gather metals, fasteners, and sealing compounds as specified in your blueprint.

- Safety Gear: Wear goggles, gloves, and a face mask for protection during cutting and welding.

Organize your plans and blueprints for easy reference. Cover your work area with durable tarps to protect against spills and debris. Ensure proper ventilation, especially when working with metals and chemicals. Having a first-aid kit nearby is also recommended. A well-prepared workspace ensures efficiency and safety throughout the assembly process.

Maintenance

Regular maintenance is crucial for the longevity and efficiency of a steam engine. Start by inspecting all components, including the boiler, cylinders, and pistons, for wear or damage. Clean surfaces and moving parts thoroughly to prevent corrosion and friction.

- Lubrication: Apply high-quality grease or oil to moving parts to reduce friction and wear.

- Boiler Care: Check for scale buildup and corrosion. Descale regularly and ensure proper water treatment.

- Pressure Monitoring: Maintain recommended pressure levels to avoid overloading the system.

- Replacement of Parts: Replace worn seals, gaskets, and valves promptly to prevent leaks and inefficiency.

Refer to your steam engine plans for specific maintenance schedules and procedures. Use durable materials and tools to ensure repairs are long-lasting. Regular upkeep not only extends the engine’s lifespan but also ensures safe and optimal performance. Always follow safety guidelines during maintenance to avoid accidents.

Safety

Safety is paramount when working with steam engines. High-pressure steam can cause severe burns, and improper handling of machinery may lead to accidents. Always wear protective gear, including gloves, goggles, and a face mask, when operating or maintaining the engine.

- Pressure Control: Ensure all valves and gauges are functioning correctly to maintain safe pressure levels.

- Proper Ventilation: Operate the engine in a well-ventilated area to prevent the accumulation of steam and reduce the risk of asphyxiation.

- Emergency Procedures: Keep a fire extinguisher nearby and have a plan in place for emergencies, such as sudden pressure release or mechanical failure.

- Training: Familiarize yourself with the engine’s operation and maintenance through the provided blueprints and guidelines before use.

Regular inspections and adherence to safety protocols are essential to prevent mishaps. Always follow the instructions outlined in your steam engine plans and consult professionals if unsure about any aspect of operation or maintenance.

Resources

Steam engine plans and blueprints are widely available online as free PDF downloads. Websites like john-tom.com offer detailed drawings for model and full-size engines, ensuring accuracy and functionality for both hobbyists and professionals.

- PDF Files: Easily accessible and printable for convenient use.

- Technical Drawings: Provide precise measurements and assembly instructions.

Where to Find Plans

Steam engine blueprints and plans are readily available online, offering detailed designs for both model and full-size engines. Websites like john-tom.com and Harbor Freight provide free downloadable PDF files, such as the popular 43 Horizontal Steam Engine Plan. These resources include comprehensive technical drawings, part lists, and assembly instructions, catering to hobbyists and engineers alike.

Additionally, platforms like Model and Allied Publications offer historical and modern designs, ensuring a wide range of options. Many plans are specifically tailored for model steam engines, marine applications, or stationary use, making them versatile for various projects. When searching, prioritize trusted sources with clear diagrams and specifications to ensure accuracy and functionality. Online forums and engineering communities also provide valuable recommendations and support for finding reliable plans.

History

The development of steam engine blueprints dates back to the early days of steam power, playing a crucial role in the Industrial Revolution. Inventors like James Watt revolutionized steam engine design, creating more efficient models that replaced earlier, less effective engines. Historical records show that up to 1860, most road vehicles were steam-powered, operating at slow speeds until the rise of internal combustion engines.

Blueprints and plans from this era were meticulously detailed, often including specifications for boilers, cylinders, and other critical components. Many historical documents, such as the Improved Compound Robey Undertype Engine handbook, provide insights into early steam engine construction. These plans were essential for both practical applications and educational purposes, helping engineers and hobbyists alike understand and replicate steam-powered machinery.

Today, many of these historical plans are digitized and available as PDFs, preserving the legacy of steam engine innovation. They serve as valuable resources for researchers and enthusiasts, offering a glimpse into the evolution of mechanical engineering and its impact on modern technology.

Modern Applications

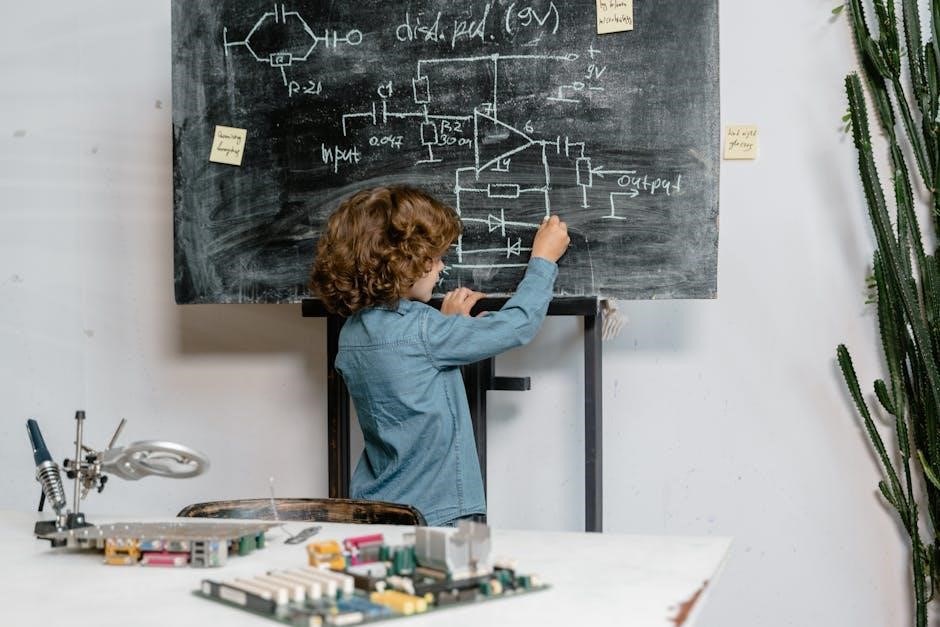

Steam engine blueprints remain relevant in modern times, with applications spanning education, hobbyism, and niche industrial uses. Many enthusiasts and educators use these plans to build model steam engines, fostering a deeper understanding of thermodynamics and mechanical engineering. The availability of PDF files and digital drawings has made it easier for students and hobbyists to access and study these designs.

In addition to educational purposes, steam engine plans are used in the construction of model trains and boats, where precision and historical accuracy are valued. Modern advancements in 3D printing and CNC machining have also enabled the creation of intricate scale models directly from digital blueprints. Some industries, such as small-scale power generation and specialized machinery, still utilize steam engine technology, relying on detailed plans for maintenance and customization.

Overall, the versatility of steam engine blueprints ensures their continued relevance in both recreational and practical contexts, bridging the gap between historical innovation and contemporary applications.

Steam engine blueprints provide a comprehensive guide for constructing and understanding these historic machines. From model steam engines to full-size designs, these plans cater to hobbyists, educators, and engineers. The availability of PDF files and detailed drawings has made it easier to access and study these blueprints, ensuring their relevance in modern times.

Whether for educational purposes, recreational projects, or preserving engineering heritage, steam engine plans continue to inspire innovation and appreciation for mechanical engineering. Their detailed specifications and step-by-step instructions make them invaluable resources for both beginners and experienced builders. As technology advances, the legacy of steam engines endures, offering a bridge between the past and future of engineering.

Ultimately, steam engine blueprints are not just technical documents but gateways to understanding the evolution of machinery and the principles that power them. Their enduring popularity highlights the timeless appeal of steam engines in both historical and contemporary contexts.